Efficient conversion of plastic into oil

Almost 30 years ago, a Japanese underwater robot first spotted a plastic bag in the depths of the Mariana Trench. Today, plastic is so widespread that it is already emerging as a new geological layer – “plastistone”. The average human brain is estimated to contain up to one tablespoon of microplastic. The severity of the problem has led the United Nations to draft a global treaty on plastics.

But because we still can't control the spread of plastic, some scientists and industries are looking for solutions. Among them, of course, is the controversial method of converting plastic back into usable oil. If effectively scaled up, "bio-oil" could power technologies that require fuel for heat and electricity, such as furnaces, turbines and diesel engines.

Researchers at Yale University recently presented a new method that increases the yield of bio-oil and reduces costs. They use pyrolysis – heating without oxygen – at 900 °C, which breaks down plastic polymers into hydrocarbons. Typically, pyrolysis achieves a 60 percent yield, but the new method without a catalyst achieves as much as 66 percent.

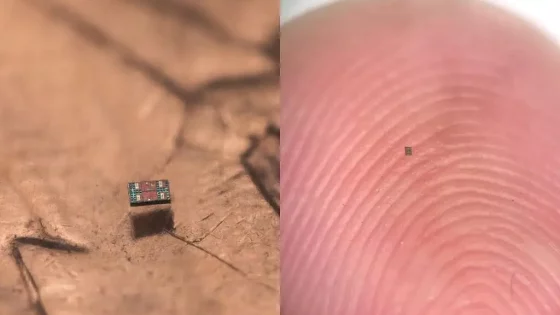

Instead of expensive catalysts, they developed a 3D-printed carbon reactor with three sections of different pores: 1 mm, 500 μm, and 200 nm. This structure controls the breakdown of molecules. An experimental version made of carbon felt achieved 56 percent efficiency, despite lower precision.

Despite the progress, challenges remain. Notably, high energy consumption, which causes carbon dioxide emissions. Some experts describe pyrolysis as a “fairy tale” promoted by oil companies to conserve fossil fuels. But innovations like Yale’s could one day become a real solution to the plastic crisis.